“Robotic, make me a chair” | MIT Information

Laptop-aided design (CAD) programs are tried-and-true instruments used to design lots of the bodily objects we use every day. However CAD software program requires in depth experience to grasp, and lots of instruments incorporate such a excessive degree of element they don’t lend themselves to brainstorming or speedy prototyping.

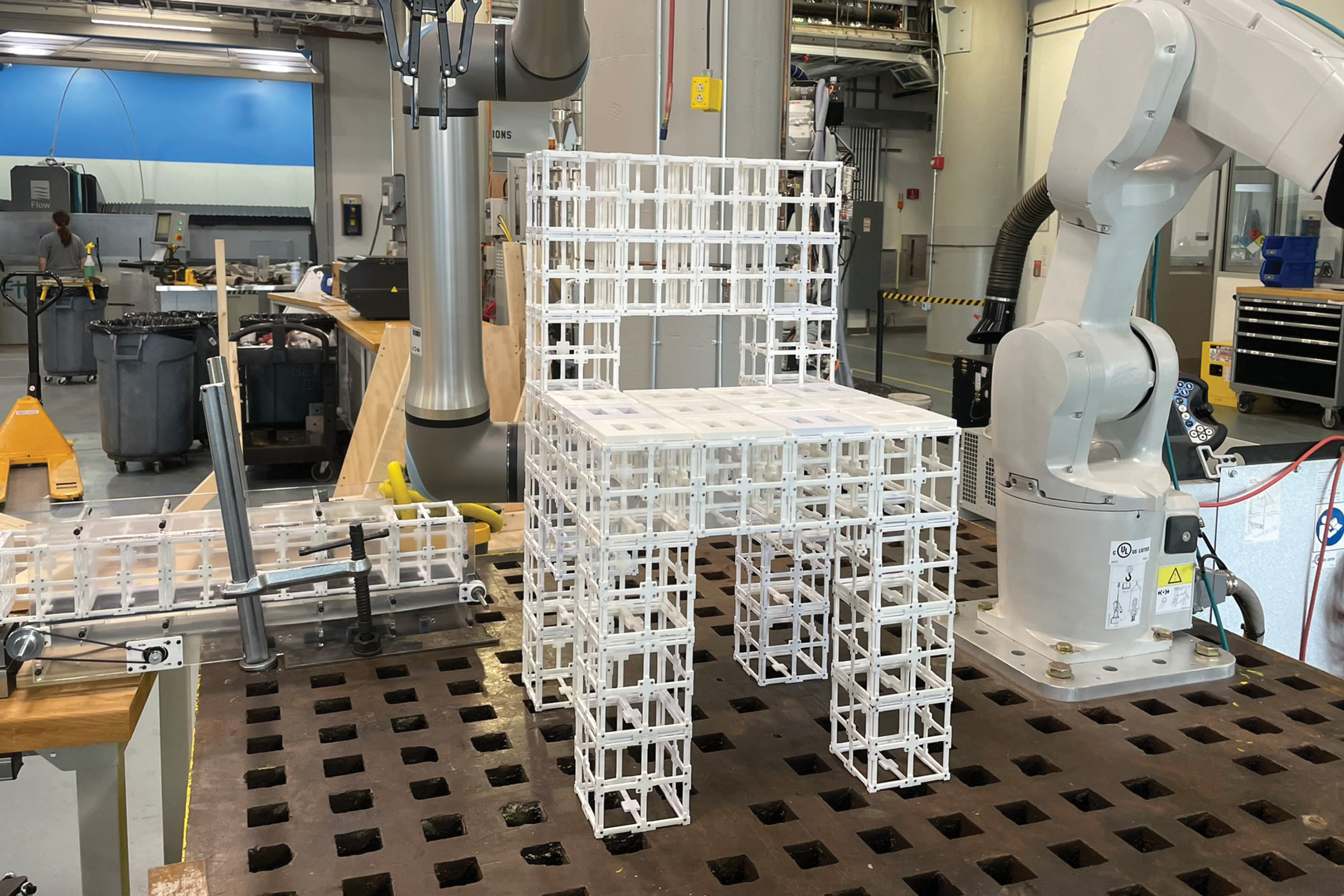

In an effort to make design quicker and extra accessible for non-experts, researchers from MIT and elsewhere developed an AI-driven robotic meeting system that permits folks to construct bodily objects by merely describing them in phrases.

Their system makes use of a generative AI mannequin to construct a 3D illustration of an object’s geometry based mostly on the consumer’s immediate. Then, a second generative AI mannequin causes in regards to the desired object and figures out the place totally different parts ought to go, in keeping with the thing’s perform and geometry.

The system can routinely construct the thing from a set of prefabricated elements utilizing robotic meeting. It could possibly additionally iterate on the design based mostly on suggestions from the consumer.

The researchers used this end-to-end system to manufacture furnishings, together with chairs and cabinets, from two varieties of premade parts. The parts will be disassembled and reassembled at will, lowering the quantity of waste generated by way of the fabrication course of.

They evaluated these designs by way of a consumer examine and located that greater than 90 p.c of contributors most well-liked the objects made by their AI-driven system, as in comparison with totally different approaches.

Whereas this work is an preliminary demonstration, the framework could possibly be particularly helpful for speedy prototyping advanced objects like aerospace parts and architectural objects. In the long run, it could possibly be utilized in properties to manufacture furnishings or different objects domestically, with out the necessity to have cumbersome merchandise shipped from a central facility.

“Ultimately, we would like to have the ability to talk and speak to a robotic and AI system the identical means we speak to one another to make issues collectively. Our system is a primary step towards enabling that future,” says lead creator Alex Kyaw, a graduate pupil within the MIT departments of Electrical Engineering and Laptop Science (EECS) and Structure.

Kyaw is joined on the paper by Richa Gupta, an MIT structure graduate pupil; Faez Ahmed, affiliate professor of mechanical engineering; Lawrence Sass, professor and chair of the Computation Group within the Division of Structure; senior creator Randall Davis, an EECS professor and member of the Laptop Science and Synthetic Intelligence Laboratory (CSAIL); in addition to others at Google Deepmind and Autodesk Analysis. The paper was just lately introduced on the Convention on Neural Info Processing Methods.

Producing a multicomponent design

Whereas generative AI fashions are good at producing 3D representations, often known as meshes, from textual content prompts, most don’t produce uniform representations of an object’s geometry which have the component-level particulars wanted for robotic meeting.

Separating these meshes into parts is difficult for a mannequin as a result of assigning parts is dependent upon the geometry and performance of the thing and its elements.

The researchers tackled these challenges utilizing a vision-language mannequin (VLM), a robust generative AI mannequin that has been pre-trained to know pictures and textual content. They activity the VLM with determining how two varieties of prefabricated elements, structural parts and panel parts, ought to match collectively to kind an object.

“There are various methods we are able to put panels on a bodily object, however the robotic must see the geometry and cause over that geometry to decide about it. By serving as each the eyes and mind of the robotic, the VLM permits the robotic to do that,” Kyaw says.

A consumer prompts the system with textual content, maybe by typing “make me a chair,” and offers it an AI-generated picture of a chair to begin.

Then, the VLM causes in regards to the chair and determines the place panel parts go on high of structural parts, based mostly on the performance of many instance objects it has seen earlier than. For example, the mannequin can decide that the seat and backrest ought to have panels to have surfaces for somebody sitting and leaning on the chair.

It outputs this data as textual content, equivalent to “seat” or “backrest.” Every floor of the chair is then labeled with numbers, and the knowledge is fed again to the VLM.

Then the VLM chooses the labels that correspond to the geometric elements of the chair that ought to obtain panels on the 3D mesh to finish the design.

Human-AI co-design

The consumer stays within the loop all through this course of and might refine the design by giving the mannequin a brand new immediate, equivalent to “solely use panels on the backrest, not the seat.”

“The design area may be very massive, so we slender it down by way of consumer suggestions. We imagine that is one of the best ways to do it as a result of folks have totally different preferences, and constructing an idealized mannequin for everybody could be not possible,” Kyaw says.

“The human‑in‑the‑loop course of permits the customers to steer the AI‑generated designs and have a way of possession within the ultimate consequence,” provides Gupta.

As soon as the 3D mesh is finalized, a robotic meeting system builds the thing utilizing prefabricated elements. These reusable elements will be disassembled and reassembled into totally different configurations.

The researchers in contrast the outcomes of their technique with an algorithm that locations panels on all horizontal surfaces which are dealing with up, and an algorithm that locations panels randomly. In a consumer examine, greater than 90 p.c of people most well-liked the designs made by their system.

In addition they requested the VLM to clarify why it selected to place panels in these areas.

“We discovered that the imaginative and prescient language mannequin is ready to perceive a point of the practical facets of a chair, like leaning and sitting, to know why it’s putting panels on the seat and backrest. It isn’t simply randomly spitting out these assignments,” Kyaw says.

Sooner or later, the researchers wish to improve their system to deal with extra advanced and nuanced consumer prompts, equivalent to a desk made out of glass and steel. As well as, they wish to incorporate extra prefabricated parts, equivalent to gears, hinges, or different transferring elements, so objects might have extra performance.

“Our hope is to drastically decrease the barrier of entry to design instruments. We’ve proven that we are able to use generative AI and robotics to show concepts into bodily objects in a quick, accessible, and sustainable method,” says Davis.